Manufacturing capabilities

Once upon a time…

Light metal sheet carpentry was more focused for

machinery perimeter and cabin delimitation. Now it has trespassed in

the field of security, ergonomic, functional design for a better

workplace and brand recognition.

From raw material to final painting and custom assembly, all the

phases in between are mastered by our personnel.

Production Department

LASER-CUT – PUNCHING MACHINES

- Num. 1 – 2D FIBER LASER-CUT (CNC) – 4KW – WorkArea 1500 x 3000 – Max Thickness 15mm – PLATINO FIBER – PRIMA POWER.

- Num. 1 – 2D LASER-CUT CO2 (CNC) – 4KW – WorkArea 1500 x 3000 – Max Thickness 15mm – PLATINO CO2 – PRIMA POWER.

- Num. 1 – 2D FIBER LASER-CUT (CNC) SYSTEM – 6KW – WorkArea 1500 x 3000 – Thickness 25mm – GENIUS+ – PRIMA POWER. + COMBO DRAWER TOWER (10 drawers) – PRIMA POWER.

- Num. 1 PUNCHING MACHINE (CNC) WorkArea 1250 x 3300 – Max thickness: 6 mm – PEGA 357 – AMADA SCHIAVI.

SHEET METAL BENDING MACHINES

- Num. 2 BENDER 170 Ton – L = 3000 mm – AMADA SCHIAVI

- Num. 1 BENDER 125 Ton – L = 3000 mm – AMADA SCHIAVI

- Num. 1 BENDER 100 Ton – L = 3000 mm – SCHIAVI

- Num. 1 BENDER 80 Ton – L = 2500 mm – AMADA SCHIAVI

- Num. 1 BENDER 25 Ton – L = 1000 mm – AMADA SCHIAVI

SHEET METAL CALANDEL MACHINES

- Num. 1 CALANDER – L = 2000 – DAVI

- Num. 2 CALANDER – L = 1300

TIG/MIG WELDING MACHINES

- Num. 15 WELDERS MIG/TIG

LASER WELDING MACHINES

- Num. 1 LASER WELDING MACHINE 1500W (2025)

Painting

Painting and lacquering is externally fulfilled. CLP feeds more than tree painting realities in the area of Avigliana and nearby Turin. Most of the painting suppliers have automated painting chains.

Powder coating is mainly requested in the realization of housings and CLP follows customer’s technical specifications or is able to suggest valuable solutions.

Assembly

The configuration of supplied items is realized in accordance to customer’s requests.

Assembly of components or groups is managed internally in dedicated areas to avoid bottlenecks that might interfere with other productive phases.

Mounting areas are sometimes overlapped to industrial painting facilities for the aesthetical most demanding items to improve lighting correction in case of flaws detection in the finishings.

Configuration of the supplied items range from partial to the-most-complete-possible housings/cabins, managing installation activities of non-carpentry parts (pneumatic system, electric actuation, electric systems and more).

Our assembly team can carry on assembly activities directly at the customer’s place.

Quality

Very important efforts are focused in checking all the production phases and suppliers are visited with almost daily cadence.

Integrated systems are internally realized and tuned to allow checklist generation and recording, correction report, tracking of items and flexibility in production management to supply spare parts to customers.

Thanks to these aspects items can be sometimes shipped in the same day they are requested. CLP works with global groups and we have the intention to keep improving.

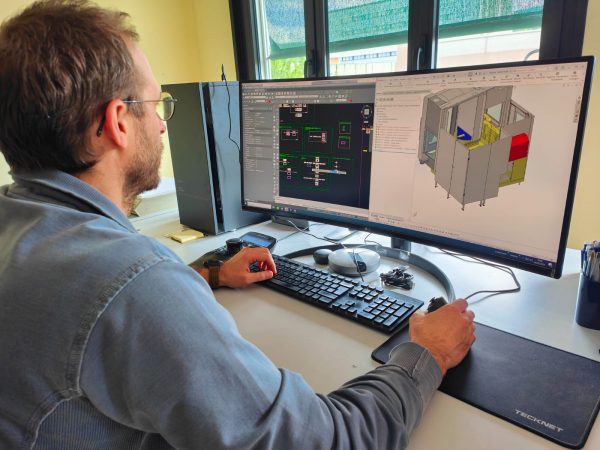

Design Office

Design office can manage activities from projects from scratch to simpler activities of shape development on metal sheets format.

Design activities are tackled in 3D modeling in pro-active relation with the customer to meet all the security and requirements and propose new solution offered by the market.

Design activities are powered by SolidWorks, SolidEdge and Catia.

We are not afraid to make a too fancy 3D model feasible, by meeting design, practical solutions and… COSTS!

We introduce ourselves

CLP is a family led enterprise and as a family all the tasks are tackled with seriousness. A family care about all its components and this allowed to ensure high quality on all the products sent to the customers.

If you are looking for

a good dress

CLP could be

the right tailor.

Locate near the city of Turin, at the base of the western Alps, CLP operates from more than 20 years in the metal carpentry field. All the activities deal with the realization of housings and external repairs mainly for the milling machine market. CLP’s customers are enterprises that request the realization of partial or complete housings for their product portfolio.

During the decades CLP dealt with the change of problematics that arose together with new features that are requested on production machines: security, design, logistic, custom production. None of these tasks worry us.

Spin off

To stregthen CLP’s production capabilities a spin-off has been created in 1997 under the name of MITAI. The enterprise is indipendent and active mainly in the food and enologic maket. It is strongly powered with integrated CNC fiber-laser cut machines with automated feed system. This aspect allows MITAI to be an important cutting/bending service center for CLP.

MITAI is certified Industry 4.0 and fully takes advantage of integrated systems to make the production quick and controllable in real time. To better know MITAI please visit: www.mitai.it